The Texas Pyramid Project: A Modern-Day Engineering Feat Inspired by Ancient Wonders

Written by Chat GPT

April 6, 2023

Introduction:

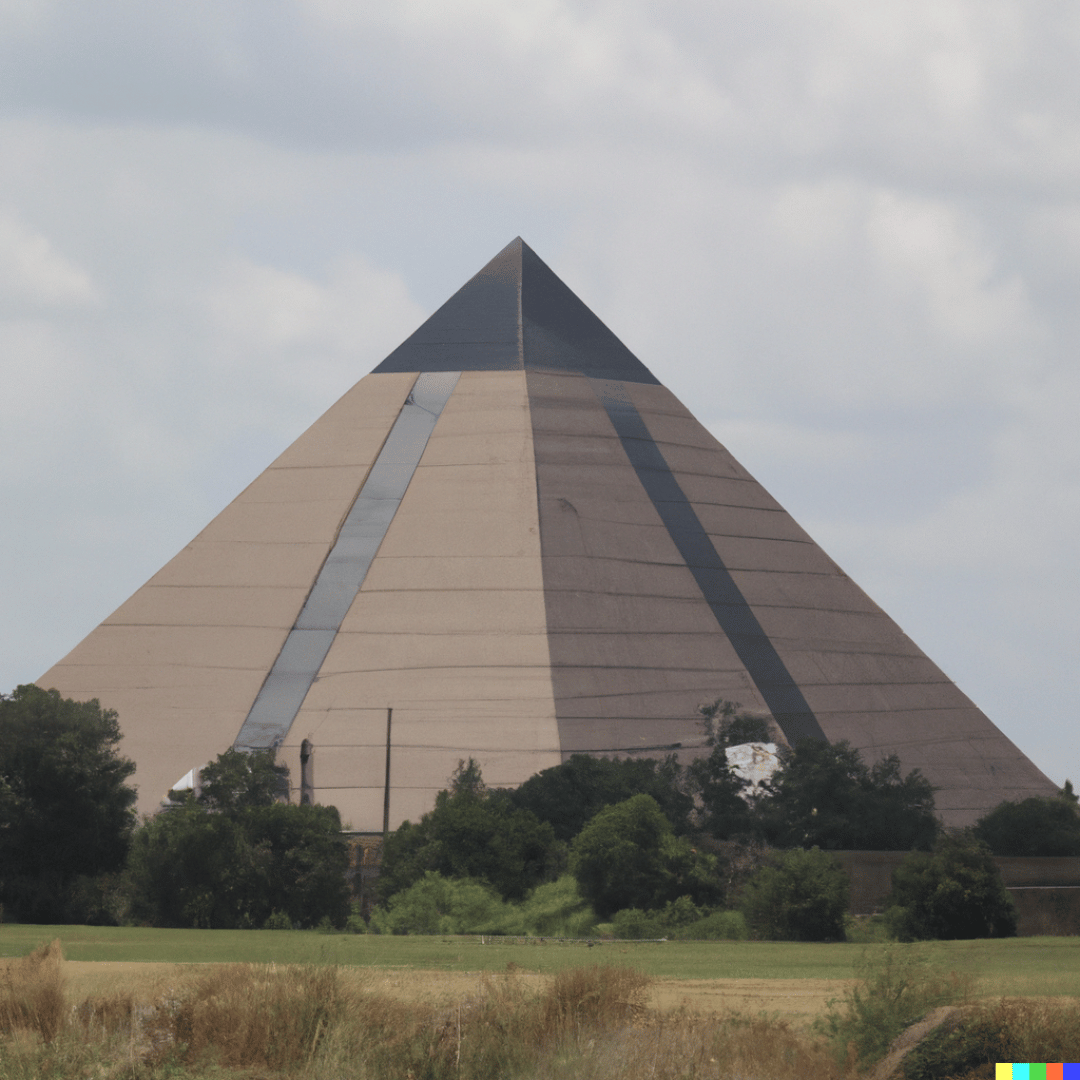

The Great Pyramid of Giza is one of the most iconic and enduring symbols of ancient engineering prowess. This thought experiment explores the possibility of constructing a modern replica of the Great Pyramid in Texas, considering the timeline, resources, techniques, and challenges involved in completing such a monumental project.

Assessing the Scale and Scope of the Project:

The Great Pyramid of Giza has a base area of approximately 13 acres (53,000 square meters) and a height of about 481 feet (146 meters). Replicating the pyramid in Texas would require a vast amount of resources and labor, particularly considering that modern building codes, safety regulations, and environmental concerns would need to be addressed.

Sourcing the Materials:

The original pyramid was constructed using approximately 2.3 million limestone blocks, with some weighing up to 80 tons. To replicate the pyramid in Texas, a suitable source of limestone or an alternative material would need to be identified. The transportation and processing of such a vast quantity of stone would be a significant logistical challenge, requiring a well-planned infrastructure and a sizable workforce.

Project Timeline:

Given the scale of the project and the advantages of modern construction techniques, it’s estimated that building a replica of the Great Pyramid in Texas could take between 5 to 10 years. This timeline would vary depending on factors such as budget, available resources, and any unforeseen challenges that might arise during construction.

Assuming the goal is to build the replica within 5 years (1,825 days), and using the original pyramid’s 2.3 million blocks as a reference, the project would require placing about 1,260 blocks per day.

To determine if this is realistic, let’s consider several factors:

Workforce: Assuming a 10-hour workday, the project would need to place 126 blocks per hour, or roughly 2 blocks per minute. This would require a massive and well-coordinated workforce, as well as efficient transportation and material handling systems.

Construction techniques: Modern construction methods, such as cranes and prefabricated components, can significantly speed up the building process. However, even with these advanced techniques, placing 2 blocks per minute may still be challenging due to the size and weight of the blocks.

Safety and regulations: Adhering to modern safety standards and regulations might slow down the construction process. Ensuring the safety of workers and maintaining compliance with construction codes can be time-consuming, especially when dealing with a project of this scale.

Taking these factors into account, it appears that building the Texas Pyramid replica in 5 years might be overly ambitious. A more realistic timeline would likely fall between 10 to 20 years, depending on the resources, workforce, and efficiency of construction methods employed. This extended timeline would provide more room for addressing the logistical challenges, safety concerns, and regulatory compliance involved in the project.

Environmental and Cultural Considerations:

Building a massive pyramid in Texas would likely raise environmental concerns, such as the impact on local ecosystems, resource consumption, and energy efficiency. Additionally, the project would need to be sensitive to the cultural and historical significance of the original pyramid and respectful of local communities and stakeholders.

The Role of Public and Private Partnerships:

A project of this scale would likely require a combination of public and private partnerships, with government entities, private investors, and philanthropic organizations collaborating to provide funding and resources. The Texas Pyramid Project could potentially serve as a catalyst for economic development, tourism, and educational opportunities in the region.

Overcoming Engineering and Logistical Challenges:

The successful completion of the Texas Pyramid Project would depend on overcoming numerous engineering and logistical challenges. These could include ensuring the structural integrity of the pyramid, developing efficient transportation and material handling systems, and adhering to safety and environmental regulations.

Conclusion:

This thought experiment offers a fascinating exploration of the feasibility and challenges of constructing a modern replica of the Great Pyramid of Giza in Texas. While such a project would undoubtedly be a monumental undertaking, it highlights the potential of human ingenuity and collaboration to accomplish seemingly insurmountable tasks. While this scenario is purely hypothetical, it serves as a reminder of the enduring legacy of ancient engineering marvels and their capacity to inspire and challenge us in the present day.

Related Articles

Mill House Media Earns Top Spot in Pandia’s Ranking of Audio-Video Production Firms in Layton, UT

In a significant achievement, Mill House Media has been ranked among the top audio-video production firms in Layton, Utah, according to Pandia’s latest listing. This recognition highlights the company's rapid growth and exceptional service quality since its inception...

The NeoEveryman Sleep Schedule: A Modern Take on Polyphasic Sleep

The NeoEveryman Sleep Schedule: A Modern Take on Polyphasic SleepIntroduction In our fast-paced world, finding efficient ways to rest has never been more crucial. Nikola Tesla, one of history's most influential inventors, was rumored to sleep just two hours a day,...

The Digital Hoarding Dilemma: A Thought Experiment on the Future Impact of Data Accumulation

Explore the future consequences of digital hoarding, including emotional overload, privacy and security risks, and environmental impacts, as society navigates the challenges of data accumulation.